The characteristics of the industrial chemicals sector are diversified in terms of products for all technical and economic areas, from which the industrial chemicals sector can exploit all the strengths of the country’s resources from mineral, oil and gas to products, by-products and even industrial and agricultural waste … Chemical industry plays an extremely important role in the economy of a country. That is a key economic-engineering sector of the country

Chemical products are less competitive with countries in the same region and Vietnam is less aware of chemical risks. This leads to the loss of natural resources and the country is also facing serious environmental problems

Chemical pumps are commonly used in the chemical, cosmetic and other industries that require the use of chemicals such as the food industry, the pharmaceutical industry.

Chemical pumps do not have as diverse materials as other types of pumps which are usually plastic materials. Some cases of the chemical pump using stainless steel but with stainless steel requirements of 316 and above and absolutely avoid pumping concentrated acids and HCL acid.

Especially with this material, chemical pumps can not withstand high pump temperatures and can not run dry. Normally under 40 degrees C, chemical pumps can operate normally, only in some cases where the pump is able to withstand temperatures of <40 degrees Celsius.

Chemical pumps have many applications in life and modern industries

– Applications in the printing industry

– Applications in the paint industry

– Applications in chemical testing, scientific research

– Applications in the rubber, asphalt, liquid glass, …

In addition, chemical pumps have many other applications depending on the needs of users.

There are many ways to classify chemical pumps, the most typical of which is the chemical pump classification in the way it works. There are two types:

– Magnetic- driven chemical pumps

– Direct-driven chemical pumps ”

List of pumps used in chemical industries:

- Centrifugal Process Pumps

- Gear Pumps

- Slurry Pumps

- Diaphragm pumps

- Regenerative turbine pumps

Now below we discuss pumps, their characteristics & technical specification:

Centrifugal Process Pumps:

Centrifugal Process Pumps are the most commonly used pumps in all the chemical industries. Centrifugal pumps are manufactured to handle highly corrosive or toxic chemicals or liquids with superior efficiency.

A high-quality impeller that is used in our centrifugal pump rotates the liquid and the centrifugal force generated in the pump push the liquid to move out. The impeller is the device that rotates and transfers energy to the fluid. Centrifugal pumps are perfect for the chemical industry because they are exclusively developed to transfer corrosive liquid & harmful chemicals.

Salient Features:

- Ease of operation: centrifugal pump will max out on the pressure at its dead-head pressure. This will not cause any damage to the system and it is easy to say able to work at medium to low head

- Can deal with large volumes of liquid

- Small in size, which saves a lot of space

- Low capital cost

- Easy maintenance

- No danger creates if discharge v/v is closed while starting

- Is able to work for medium to low viscous fluid

- Continuous pulsation-free delivery

- Less wear and tear in case of corrosive and abrasive liquids

Gear Pumps:

Gear pumps manufactured to handle and transfer high corrosive liquids or chemicals with superior efficiency.

A rotary gear pump uses the positive displacement principle to pump the liquids. The pump has a casing with dual gear and crescent assembled in a curved shape. While in a process when the rotor gear started to turn, the gear rotates with the teeth beginning to mesh. The space between the gears and the meshing action which pump the fluid to displace is why the positive displacement name is given.

Salient Features:

- Highly efficient performance

- Compact design

- Easy maintainable

- Easy cleanable

- Low noise

- Low leakage path

- Non-corrosive

- High speed

Slurry pumps:

Slurry pumps manufactured to handle aggressive liquid in chemical plants.

The Working Principle of a slurry pump is that slurry enters the pump through the eye of the rotating impeller which imparts a circular motion. The slurry is forced outwards by centrifugal force and moves between the blades of the impeller.

The slurry attains a high speed by the time it reaches the edge of the impeller. In the casing, its high-speed force is transformed into pressure energy. The pumps increase the pressure of a liquid and solid particle with the help of centrifugal force and convert electric energy into kinetic energy to pump the slurry. This mechanism makes pumping dangerous and light slurry liquids easy and maintenance-free.

Salient Feature:

- Made maintenance quick and easy

- Replacement of wearing parts can be done in the field.

- With the two parts casing, it is possible to replace the worn front cover without changing the complete casing.

Diaphragm pumps

Diaphragm pumps are positive displacement pumps that move gases, liquids or gas-liquid mixtures via a reciprocating diaphragm. They do not have any internal wear components due to the simple diaphragm design, making them highly reliable pumps. They also do not require sealing or lubricating oils within the pumping head, so there is no chance of oil vapour leakage or contamination of the handled media.

Simple diaphragm pumps consist of a diaphragm, displacement chamber, two valves and a driving mechanism. The diaphragm is made of a flexible material and must be checked for compatibility with the chemical to be pumped. It is sealed in place between the side of the displacement chamber and an attached flange. The chamber’s volume is slightly greater than what the diaphragm can displace.

Regenerative turbine pumps

Regenerative turbine pumps also referred to as vortex or periphery pumps, use turbine-like impellers with radially oriented teeth to move the fluid. Turbine pumps combine the high discharge pressures of positive displacement or multi-stage centrifugal pumps with the flexible operation of centrifugal pumps. Unlike most centrifugal pumps, the flow rate of turbine pumps does not vary greatly with large changes in pressure.

They are preferred in applications where the high head, low flow, and compact design are desired but are unsuitable for solid-liquid mixtures. When a turbine pump is to be used for chemicals, the internal clearances must be sufficient to prevent rubbing, which would decrease efficiency.

Chemical Pump Selection – Application Requirements and Attributes

The first step in chemical pump selection is a proper understanding of the application requirements and the chemical media properties along with selecting the pump with the specifications to perform the task. The following graphic lists some of the main criteria to consider during chemical pump selection.

Chemical Pump Certifications

Certain industries and applications have specific codes, standards, and regulations that need to be met. In some cases, a pump must meet or be certified to these standards (ASME, ANSI, API, NACE, etc.) before it can be used in certain boiler, pressure vessel, oil and gas refinery, nuclear or other mission-critical applications.

Industrial chemical pump brands

Applications of chemical dosing pumps in practice:

Pumping petroleum, minerals, gasoline.

Pumping acids, bases, chemicals in laboratories, factories.

Pumping ink, paints, glues, fabric dyes.

Pumping factories and industrial wastes containing main ingredients are chemicals and corrosive substances.

Thai Khuong is proud to be the largest supplier of pumps in Vietnam up to the present time. We specialize in distributing industrial chemical pumps with long-standing brands from EU, US, UK, G7, etc. Our partners are famous brands:

- Jessberger (Đức)

- Wright Flow (USA)

- Doseoro (Italy)

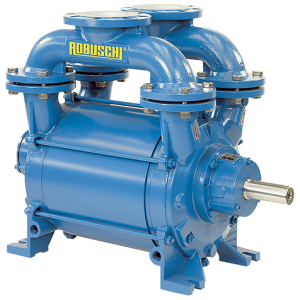

- Robuschi Robox (Italy)

- Caprari (Italy)

- Salvatore Roboschi (Italy)

- FTI Finish Thompson

- Gemmecotti (Italy)…

Chemical pump lines are available in Thai Khuong.

Centrifugal Pumps

Centrifugal Pumps

DP BLOCK CENTRIFUGAL MONO-BLOCK SINGLE STAGE PUMPS – DP PUMPS

Centrifugal Pumps

CMO-N Horizontal centrifugal pumps with mechanical seal – AFFETTI

Chemical Pumps

Centrifugal Pumps

Centrifugal Pumps

Centrifugal Pumps

Centrifugal Pumps

Centrifugal Pumps

CDM Horizontal centrifugal pumps with mechanical seal – Affetti

Centrifugal Pumps

Centrifugal Pumps

CGD Horizontal centrifugal pumps with mechanical seal – AFFETTI

Centrifugal Pumps

CGO Horizontal centrifugal pumps with mechanical seal – Affetti

Centrifugal Pumps

Centrifugal Pumps

Dosing Pumps

Centrifugal Pumps

Vacuum Pumps

Vertical Pumps

Submersible Mixer

Submersible Pumps

Centrifugal Pumps

RS Centrifugal pumps with vortex impeller – Salvatore Robuschi

Centrifugal Pumps

RB Centrifugal pumps with channel impeller – Salvatore Robuschi

Centrifugal Pumps

RAM Double-stage with peripheral impeller pumps – SALVATORE ROBUSCHI

Centrifugal Pumps

HG Centrifugal pumps with semi-open impeller – SALVATORE ROBUSCHI

Centrifugal Pumps

HD Centrifugal pumps with closed impeller – SALVATORE ROBUSCHI

Centrifugal Pumps

RD Centrifugal pumps with closed impeller – Salvatore Robuschi

Centrifugal Pumps

RG Centrifugal pumps with open impeller – Salvatore Robuschi

Centrifugal Pumps

RC Centrifugal pump with vortex impeller – SALVATORE ROBUSCHI

Vacuum Pumps

Centrifugal Pumps

Centrifugal Pumps

Centrifugal Pumps

Centrifugal Pumps

Centrifugal Pumps

Centrifugal Pumps

Centrifugal Pumps

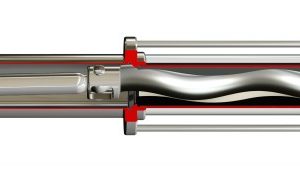

Progressing Cavity Pumps

Progressing Cavity Pumps

Progressing Cavity Pumps

Progressing Cavity Pumps

Progressing Cavity Pumps

Air Diaphragm Pumps

Air Diaphragm Pumps

Centrifugal Pumps

Centrifugal Pumps

Centrifugal Pumps

Air Diaphragm Pumps

Drum Pumps

Drum Pumps

Drum Pumps

Drum Pumps