MAINTENANCE OF MUD PUMP: INSTRUCTIONS NEEDED FOR USERS

Sludge pump maintenance should be done regularly and periodically to ensure that your slurry pump is operating in the best condition.

Thai Khuong would like to share the article on the most common preventive maintenance steps arising from the mud pump, regardless of brand.

The list is based on the most common incidents users encounter when operating a slurry pump

SO HOW TO ENSURE PROPER MAINTENANCE OF YOUR SLURRY PUMP?

Step # 1: Check the belt

When should you check the belt of the slurry pump?

If the slurry pump is driven by a belt, please check the tension of the rope at least once a quarter. Too tight belts will cause damage to the motor bearing and once the bearing is broken the bearings will start to fail inside the pump. Belt that is operated when it is too loose will cause poor performance and cause slip damage to the belt.

* Note extra must check new belts 5-7 days after installation to ensure proper tension.

Step # 2: Check the oil

When should you change the oil for the pump?

If your dredge pump is using lubricant for cooling, please check it periodically to make sure there is no water or other impurities in the oil. If the pump seal remains stable, changing the oil periodically will increase the life of any pump.

Step # 3: Check for gaps in the wing

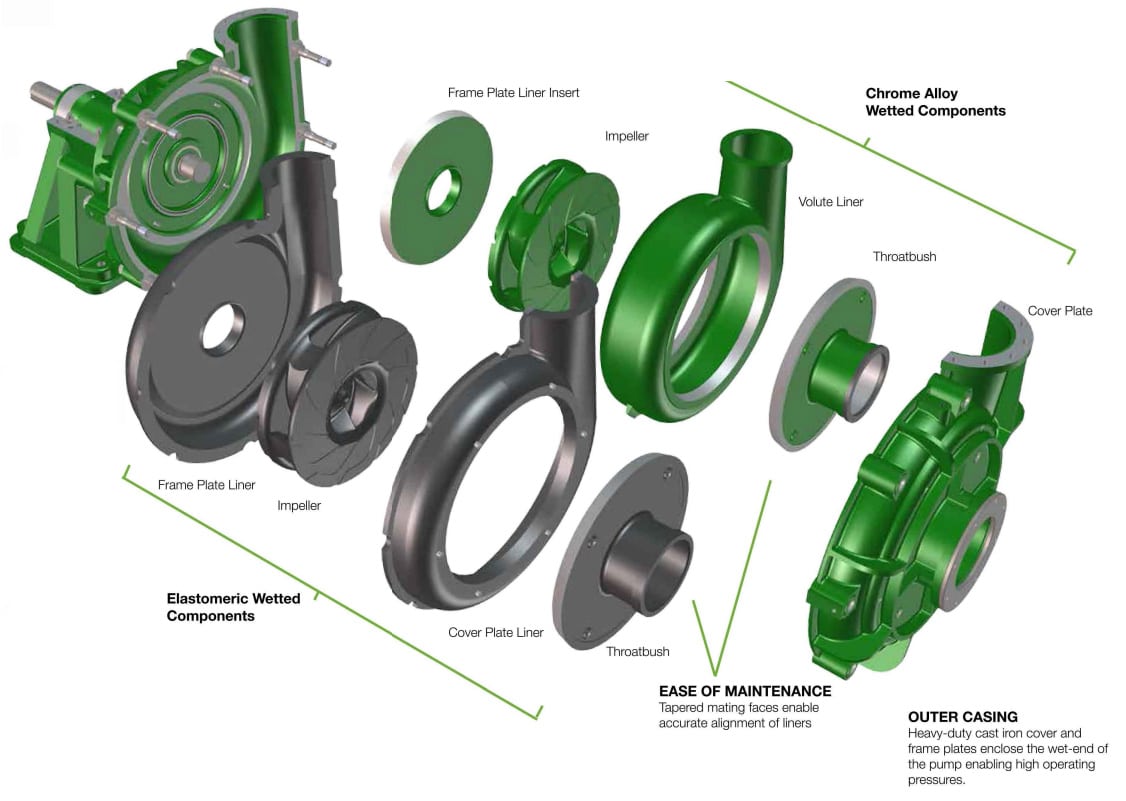

Best performance is achieved by occasionally checking the out-of-wing clearance. Refer to instructions to check gaps appropriately. When checking the clearance, it is also necessary to check the impeller wear and other parts of the dredge pump.

The protective layer in pump body sets when abraded can increase the clearance causing a loss in performance.

Abrasion may be caused by the abrasion of the pumped fluid or by excessive pump operation of the performance curve designed for the pump.

Step # 4: How to evaluate and ask for mud pump maintenance

Sometimes mining systems and operating processes change in design, capacity, etc., but we continue to use the same equipment without considering changes to the operating process. could have been done in the mining system.

For this problem, the best solution is to install pressure gauges and flowmeters on the discharge lines of the pumps. You can take the display pressure and multiply it by 2.31 to get the relative TDH (total dynamic head). You can then take that TDH along with the measured flow and see if your pump runs near the BEP (best efficiency point) on the pump’s baseline. If not, please contact your provider.

Step # 5: Manage temperature when operating mud pump

Temperature sensors are provided with our submersible pumps for engine protection. Each guide provided with the pump will outline how to connect and monitor the temperature sensors for the maximum life cycle.

why do you need care?

If the engine is overheated, the sensors will automatically shut off and the pump will stop working until the engine cools down. If there is no sensor, or the sensor is not connected to the pump, there is a risk of engine fire.

WHEN SHOULD YOU TEST YOUR TEMPERATURE PUMP?

Horizontal and vertical pump cantilever need to check the temperature of the bearing weekly while the pump is in operation. Use a temperature gun to check the bearing housing temperature closest to the bearing.

At what temperature should the pump be operated?

While most pump bearings run in the range of 140 to 170 degrees Fahrenheit, it is recommended that users never allow temperatures in excess of 200 degrees Fahrenheit (about 94 degrees Celsius). High bearing temperatures may be a sign of excessive lubrication or a problem with the bearing.

Step # 6: Watch the suction pump head bearing

Using some vibration-measuring devices will tell us if bearings begin to show signs of damage.

Vibration analysis should be performed by qualified and trained engineers / technicians with experience in this type of work.

Proper vibration monitoring will provide the operating team with useful information that can increase MTBF (mean time between failures) and improve pump performance. Refer to the Hydraulic Institute’s vibration monitoring guide (American Hydraulic Institute) for vertical, horizontal and submersible pumps for appropriate limits.

Learn about other pumps:

Currently Thai Khuong Pump is representing the pump brand Schuro Slurry in Vietnam specializes in providing products with large capacity US brand mud pump (you can refer to the products here).

If you have not yet selected a suitable mud pump product, or have any questions need advice or provide technical information, product prices. Let’s contact right with us.

Thai Khuong Pumps Always ready to listen and support you.