A mixed flow pump is a type of pump that combines the features of radial and axial pumps. Why this combination? What are they used for? This article will give you the answer!

What is a mixed flow pump?

A mixed flow pump, also known as a mixture pump, is a centrifugal pump with a rather special mixed flow pump impeller. Specific speed (ns) ranges from 35 to 80 rpm for low-speed mixed-flow pumps and from 80 to 160 rpm for high-speed mixed-flow pumps (in special cases even higher). The mixed flow pump is located between the transition between the radial-pump and the axial flow pump (e.g. vane pump).

The impellers of low specific speed mixed-flow pumps are combined with annular or arc-shaped housings; Mixture pumps with higher specific rates are combined with diffusers and tubular housings.

General characteristics of the mixed flow pump:

-

- Compared to centrifugal pumps, mixed-flow pumps have lower lifting forces and larger flow rates. Compared to the axial pump, this pump has a higher lift force and a lower flow rate. Apply for irrigation of plains and ponds.

- Water is sucked and discharged at a certain angle concerning the impeller shaft along the flow direction of the mixed flow pump, so it is also called a cross-flow pump.

Construction of a mixed-flow pump

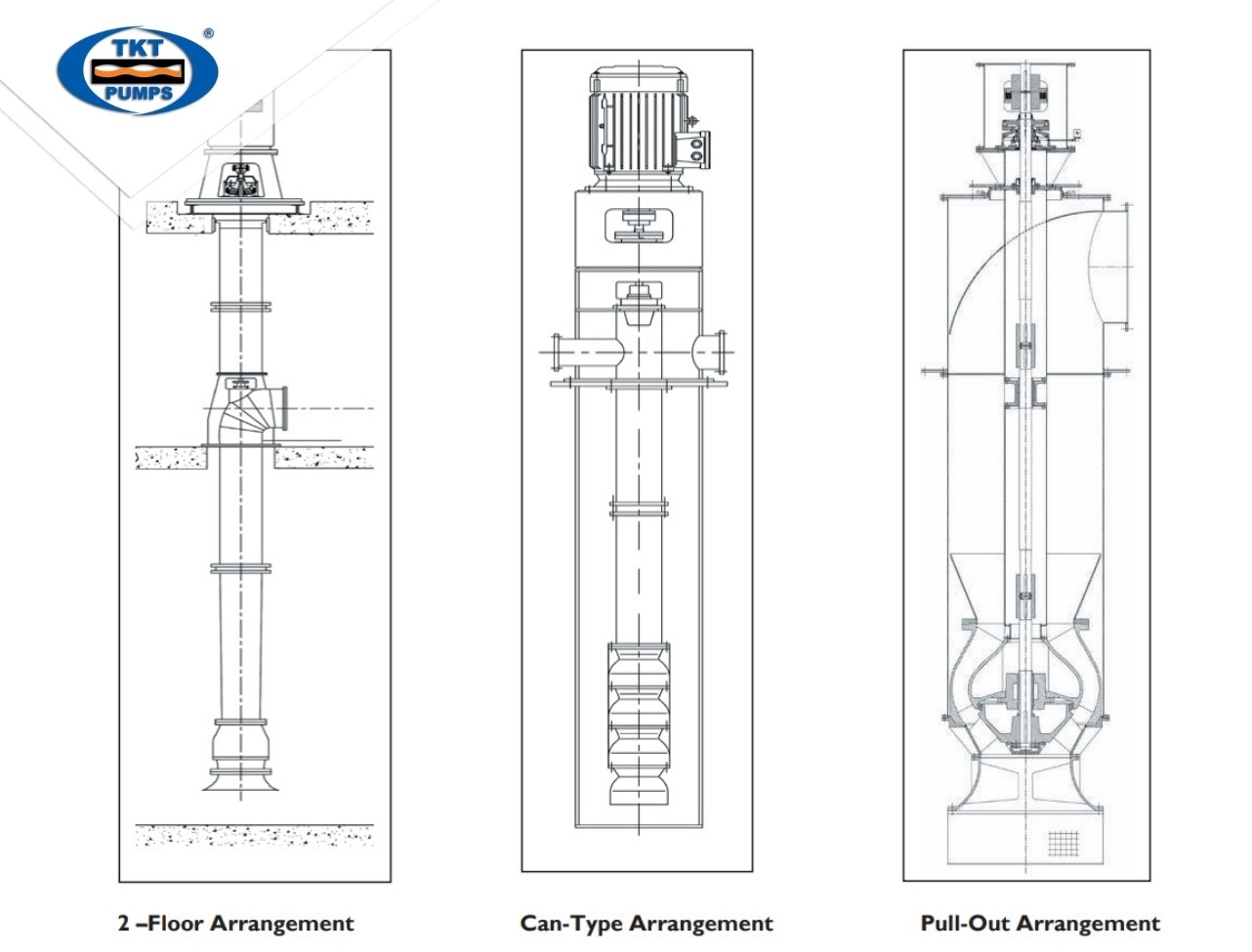

The mixed flow pumps are mainly designed with a single-stage vertical configuration incorporating a diffuser.

However, horizontal and vertical designs with coil housings, as well as a two-stage design are additional options for this series of mixed-flow pumps.

And they come in both semi-submersible designs with suction bells and dry-place designs with a suction pipe. The pump rotor is an impeller with fixed mixed-flow impellers. Some common configurations of common mixed-flow pumps are as follows:

-

- Vertical or horizontal shape construction

- Submerge or dry design

- Single-stage or multi-stage form

Working principle of mixed flow pump

Since the shape of the impeller of the mixed-flow pump is located between the impeller of the centrifugal pump and the impeller of the axial-flow pump, the working principle of the mixed-flow pump has both centrifugal force and lifting force.

The impeller sits in the pipe and rotates, but the rotation mechanism is essentially diagonal, using centrifugal force to move the water while accelerating it further with thrust from the impeller’s axial direction. This generates enough force to produce a high flow rate.

In summary: By the combined action of both forms of the impeller, water flows out of the impeller at a certain angle to the shaft. Lift the water through the reservoir and into the pipe to where it needs to be.

Mixture pump MW of DP

MV type mixed flow pump is a mixed flow pump with a single-stage or multistage impeller design.

Standardized components: bowl, column, discharge head, and control unit.

-

- Capacity from 130 to 23000 m³/h

- Heads up to 250 m

- Exhaust port sizes NW 200 to 1600 mm

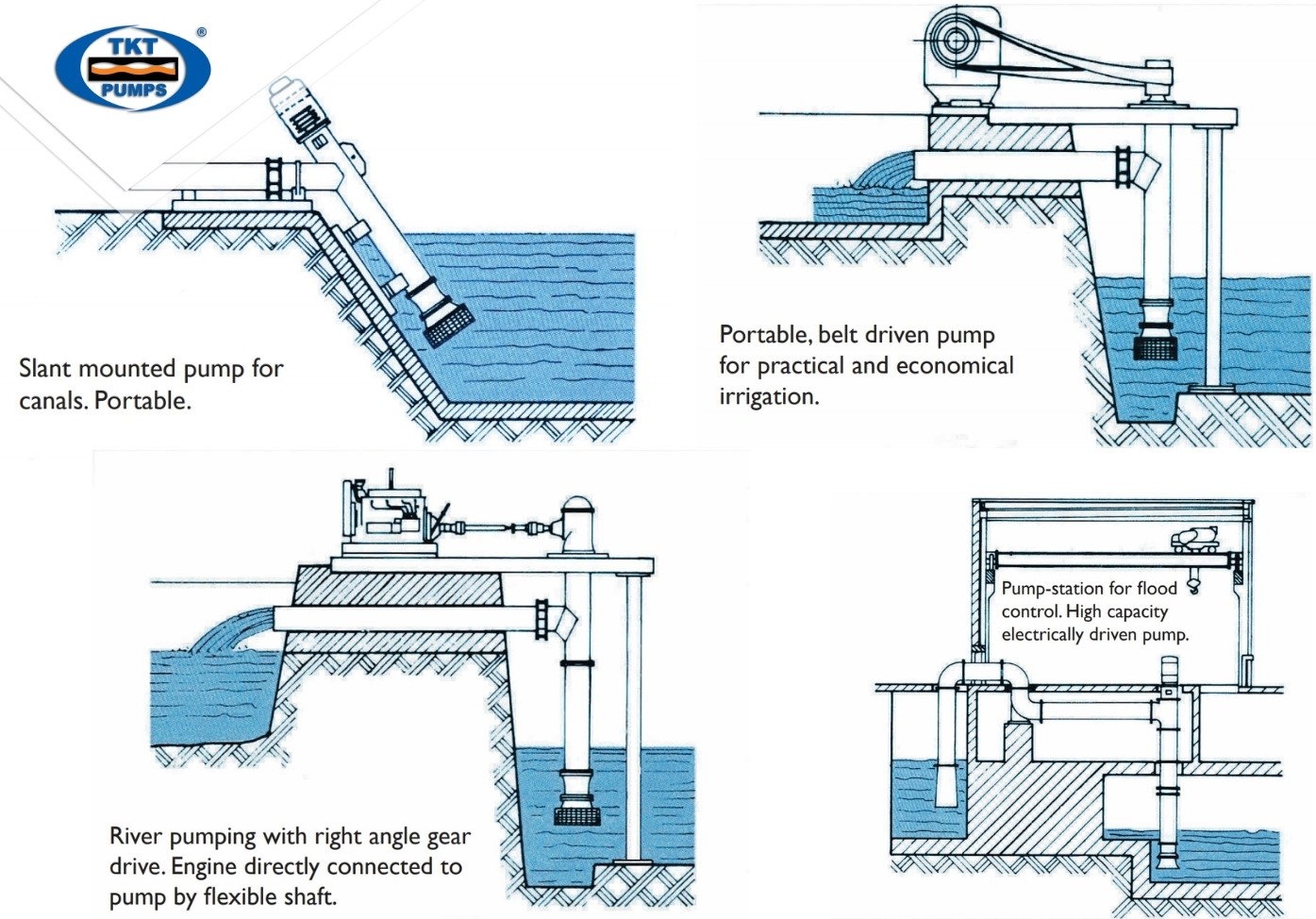

Typically, mixed-flow pumps are installed in the vertical position drawing force from the reservoir and discharging through a 90° elbow. They can be mounted horizontally if required. It is also quite common to place the pump at an angle on the ground or ditch. This reduces the cost of the pedestal structure.

Application of mixed-flow pump in the industry

Mixed flow pumps are primarily used in applications requiring high flow rates combined with relatively low discharge pressures. There are several industrial applications where this type of pump can be useful such as:

-

- It is often used to upgrade the irrigation of agricultural lands,

- Wastewater drainage applications,

- Cooling water for thermal and nuclear power plants,

- Seawater treatment,

- Industrial applications and water supply…

Thai Khuong is distributing this mixed-flow pump with models from the DP Pump brand originating from Greece. If you want to learn about this pump line, or need advice on industrial fluid handling solutions, please contact Thai Khuong immediately for quick support!