Any factory produces odors during the manufacturing process. It can be from the product processing line, from the wastewater treatment system… These odors negatively affect the health and performance of workers in the factory.

The treatment of odors to provide a solution to eliminate odors, providing a healthier environment for labor and production. So how to deal with the smell? What equipment helps to treat wastewater odors effectively?

Common Sources of Odor in Wastewater Treatment

In general, most areas of a wastewater treatment facility contain some level of odor. Depending on the location of your site, you’ll most commonly have issues in primary treatment and sludge-handling areas, in addition to these areas:

- Headworks

- Clarifiers

- Sedimentation basins

- Lift stations

- Lagoons

- Biosolids treatment

- Wastewater septage dumping

These processes can produce various odors, the most common of which found include hydrogen sulfide, ammonia, sulfur dioxide, skatoles, mercaptans, amines and indoles. Thankfully, there are various natural treatments and deployment technologies that can keep these odors at bay.

Headworks and Primary Treatment

Hydrogen sulfide odor is a serious issue found in the headworks and primary treatment areas of wastewater treatment facilities. Vapor or fan systems can solve this issue when installed at the bar screens and digesters. In some cases, the biochemical can be diluted with plant water to form a more cost-effective solution.

What kind of pump does the odor treatment industry need?

Reliability, cost-effectiveness and low maintenance are key factors that odor control system designers evaluate when they choose the pump for their system. These systems are typically one of two common types:

Biological odor control system.

These systems use irrigated inert sulfur-oxidizing bacteria to remove hydrogen sulfide and organic sulfur compounds. These gases are flammable, corrosive and toxic, and give off a strong odor. Due to their harsh nature, they must be treated before they are released into the air.

To be effective, odor control systems require pumps designed for heavy chemical exposure. And Finish Thompson is the manufacturer of specialized pumps for applications like these. The pumps used in this system can be mentioned as: drum pumps to fill odor treatment chemicals, diaphragm pumps and magnetic-driven centrifugal pumps that are responsible for pumping the fluid that needs to be treated on the system.

Chemical cleaning odor control system.

These systems use a cleaning solution to treat contaminated air so that it can be safely discharged. Cleaning solutions containing chemical reagents must be handled appropriately.

For odor removal on this system, there are typically Finish Thompson DB series pumps that are well suited for this application. “End users need a cost-effective, corrosion-resistant pump to circulate reagents in their system.

Series DB Magnetic Drive Pumps offer corrosion-resistant materials and shaftless magnetic drive technology, resulting in less downtime than sealed pumps as seals by nature deteriorate over time. and must be replaced.”

In addition, Finish Thompson pumps can be easily disassembled to replace parts. This is one of the main outstanding advantages of Finish Thompson pumps that other brands have not yet made.

Example: If you need to replace an impeller, the FTI magnetic drive pump can be easily disassembled, making repairs efficient and economical – compared to the cost of comparable sealed pumps on the market.

Custom solutions for the odor control industry.

Finish Thompson pumps not only provide reliability and low maintenance for odor control system designers, they can also provide customized solutions for each application.

Odor control system designers will often build systems according to the needs of their customers.

“They have a wide selection of pumps for large or small systems and handling different chemicals. And when they work with Finish Thompson, they get to choose from a wider range of pumps. Typically, the centrifugal pump with magnetic transmission belongs to the DB series. By customizing each system with a specific pump and delivering products to customers quickly, FTI helps play a vital role in their ability to deliver the right system for their customers. provide the right systems for their customers.”

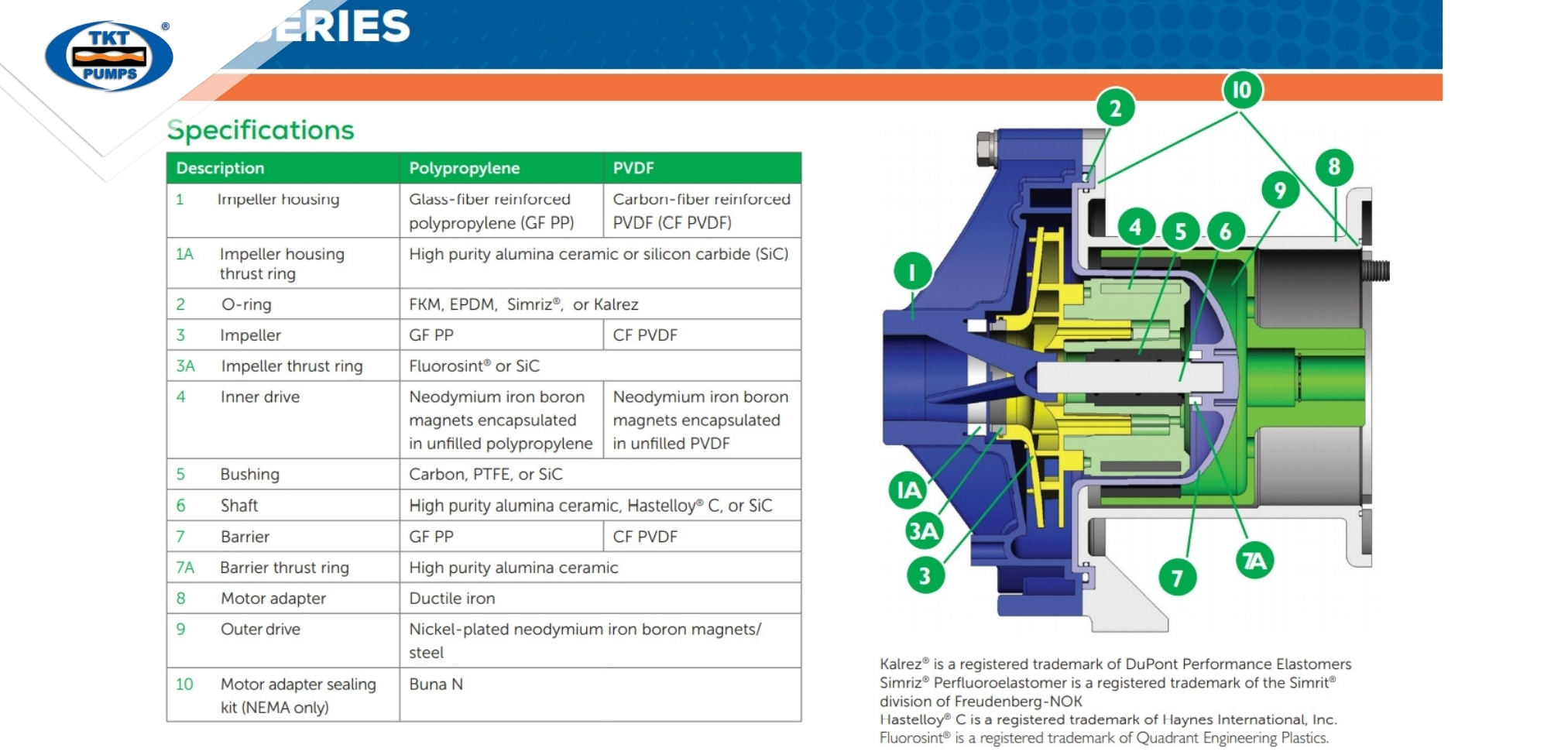

Centrifugal pump series are driven by DB Finish Thompson.

These magnetic drive pumps set the standard for handling corrosive liquids. They are designed for high performance and can run dry for hours without damage when fitted with carbon bushings.

DB Series pumps offer the best performance of any pump in their class and are available in corrosion-resistant polypropylene or PVDF construction.

The DB Series drive pumps with shaftless technology are perfect for moving irrigation fluids through the system. In addition, these Finish Thompson pumps are seal-free and have low maintenance costs.

The heavy chemicals involved in these odor treatment processes can quickly wear down mechanical seals, resulting in repair and labor costs, plus downtime that disrupts production, affecting production. company costs. By eliminating seals, which means eliminating maintenance, costs are greatly reduced.”

Above all, trust the reliability of equipment in the odor treatment industry. DB Series pumps are warranted for up to five years, compared with up to two years for similar pump brands in the market.

Where to buy Finish Thompson pumps?

Currently, FTI or Finish Thompson is being trusted in many factories in Vietnam. And Thai Khuong has also contributed a lot to the process of bringing advanced equipment from developed countries around the world to Vietnam. Helping Vietnam’s industry develop more and more, catching up with Western countries.

Thai Khuong is confident with more than 14 years of experience in the industry, will bring you the most effective solutions in treating wastewater odors through excellent pumping equipment from FTI.

Please contact Thai Khuong immediately when you are in need of FTI pump for your odor treatment system!