What are chemicals?

“A chemical or chemical substance is a form of matter whose compounds and chemical properties do not change. It is not possible to separate it into smaller components using physical separation without breaking the chemical bonds.

Chemicals come in gas, liquid, solid, and plasma states.”

That is the definition of a chemical that we have learned or read about. But did you know? We are constantly exposed to many of these chemicals daily. Which is toothpaste, shampoo, soap, perfume, …

Are chemicals harmful? Is the substance good or bad? I heard that chemicals can corrode our hands when in contact, so how to exploit and handle chemicals? Well, people often use chemical pumps with plastic heads to pump chemicals. So what’s so special about this device? Let’s find out together!

What is a chemical pump?

Chemical pumps are also common liquid pumps. But they have special textures and materials. Helps resist chemical corrosion. Therefore, the name is also a characteristic of this pump line.

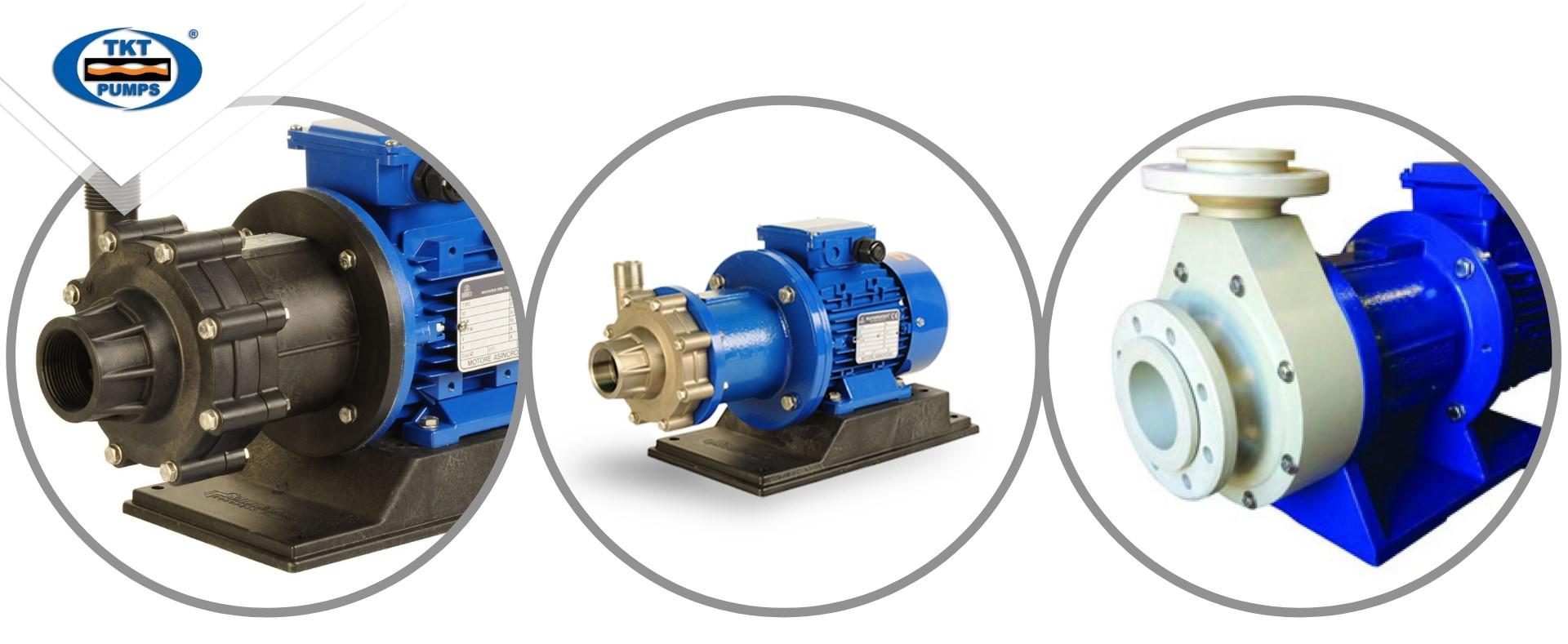

Chemical pumps have many different shapes, sizes, and operating principles.

Currently, on the market, we can easily find pumps specialized for the chemical and cosmetic industry such as:

-

- Diaphragm pumps

- Centrifugal pump with magnetic drive

- Centrifugal pump with plastic head

- Manual chemical pump

- Metering pump…

But in general, they have a common construction of plastic, which is an effective chemical resistant material. In addition, there are materials used in chemicals such as stainless steel …

In this article, we will go into depth about this pump line, plastic pump chemical pump.

Chemical pump with plastic head

A chemical pump with a plastic head is a chemical pump with a pump chamber, also known as a plastic pump head. The purpose for using PP, PPF, composite … is to resist corrosive agents from the fluid to be pumped.

Teflon is often the plastic polymer of choice due to its stronger and stronger properties. This is especially true in heavier industrial environments, but other plastics may be used, such as PVDF, Polypropylene, ABS, and Noryl.

A chemical pump must use materials that are compatible or resistant to a wide range of chemicals. For example, when pumping water, a cast iron or brass material is suitable. However, if pumped with Sodium Hypochlorite, cast iron or brass will quickly fail and begin to leak Sodium Hypochlorite into the environment.

In general, plastics have a wider range of applications and are more resistant than metals to chemicals. For example, for a chemical like Sodium Hypochlorite, you should use Kynar in the chemical pump. Some plastics have better properties than others. Kynar is better than Polyurethane or Polycarbonate, for example.

It is important to know which resin is best for the current application. Just because one plastic head pump is more expensive than another does not mean that a more expensive plastic pump will be more compatible than a cheaper pump. For example, Sodium Hydroxide is not compatible with Kynar but it is compatible with Polypropylene which is much cheaper than Kynar.

Characteristics of the chemical pump with plastic head

When choosing to buy products, we often find out the characteristics of this chemical pump line to see if it suits our requirements or not. With the plastic head chemical pump line, there are outstanding features such as:

-

- Full plastic pump head such as PP or composite

- Light-weight

- High power

- Good anti-corrosion

- Suitable for many chemicals with strong corrosive properties such as acids, abrasives, etc.

- Stable operation

- The structure is easy to operate, maintain and maintain

When to use a chemical pump with a plastic head?

You know, there are many different chemical pumps on the market. But popularly, there are chemical pumps with stainless steel heads and chemical pumps with plastic heads.

So when to use a chemical pump with a plastic head? After learning about the characteristics of this plastic pump, surely you know what the biggest strength of this chemical pump is, right?

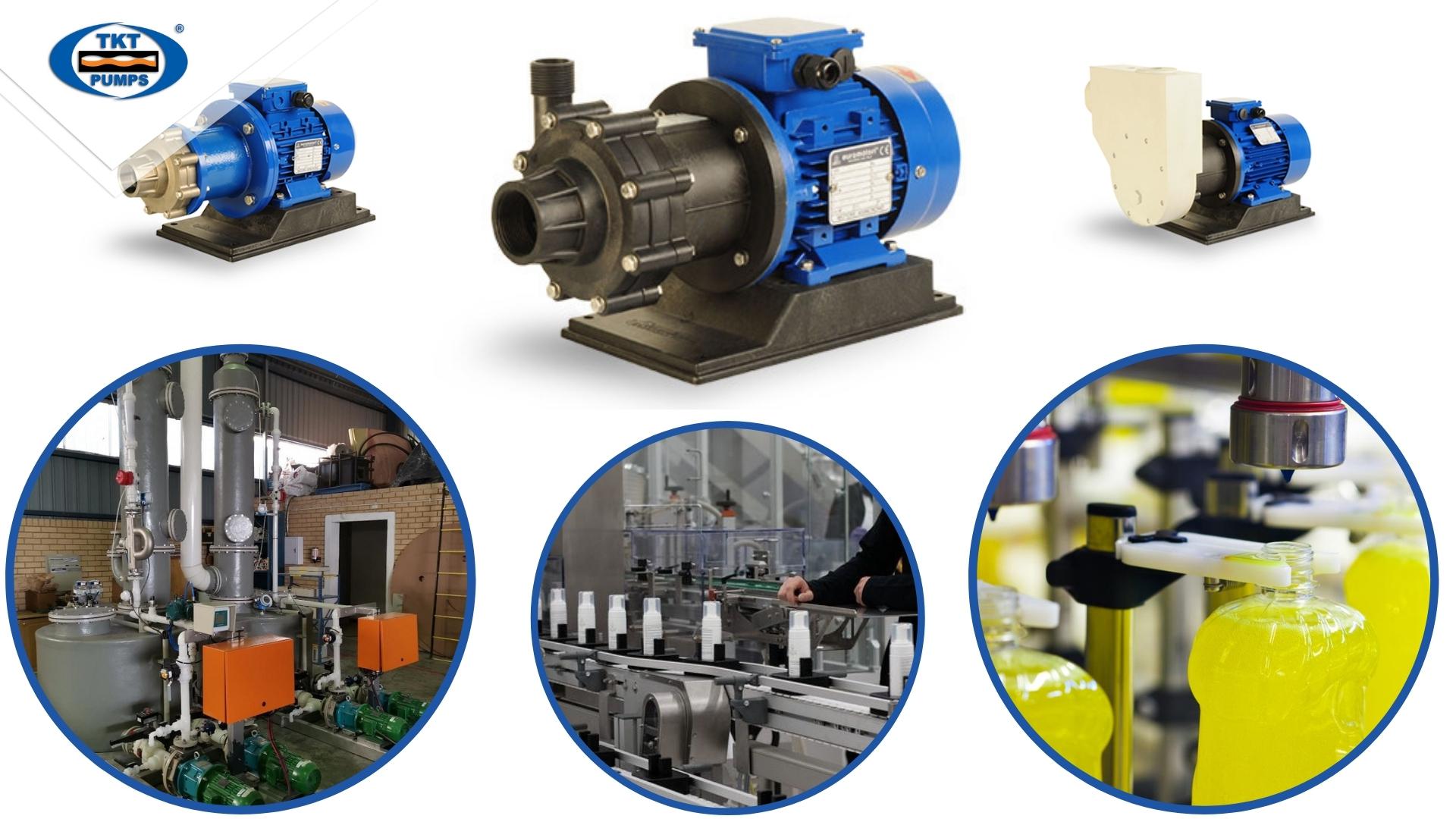

Chemical pumps with plastic heads are preferred for pumping aggressive chemicals such as acids, acids, bases, wastewater…

In addition, in food, plastic pumps are also used to pump raw materials and finished products besides stainless steel pumps…

Advantages of the chemical pump with plastic head

Plastic-head chemical pumps are generally lower-maintenance, less susceptible to damage from various liquids and materials, and cannot rust.

They are also typically lighter than metal pumps of their class and can transfer hazardous or corrosive liquids without the associated risk of leaks or accidents.

In more severe environments, plastic head chemical pumps are often cheaper than metal pumps because suitable grade metals can be very expensive.

Plastic pumps are also a better choice for maintaining water purity than metal ones, as metals can corrode and trace elements can leak into the pumped fluid.

Plastic head pumps are generally more wear-resistant and therefore reduce the risk of contamination. This is especially useful for pure fluid pumping purposes.

Disadvantages of chemical pump with plastic head

While plastic pumps are better in most cases, there are some notable downsides to using them.

They are generally more susceptible to heat damage and therefore may have lower maximum temperature limits.

Certain chemicals can also react with the plastic, disallowing the material to be used to pump that chemical. Therefore, it is necessary to consider the fluid to be pumped carefully when choosing a plastic-head chemical pump.

Where is a good place to buy chemical pump with plastic head?

Chemical pump with plastic head with a variety of origin as well as shape and size. This always makes users learn to shop equipment confused. Don’t know how to choose so as not to make mistakes.

Thai Khuong understands that, so right from the beginning, Thai Khuong has built a team of in-depth technical consultants, to support you with solutions and find the answer to the most optimal equipment investment problem…

When you need chemical pumps in general or chemical pumps in particular, please contact Thai Khuong immediately!