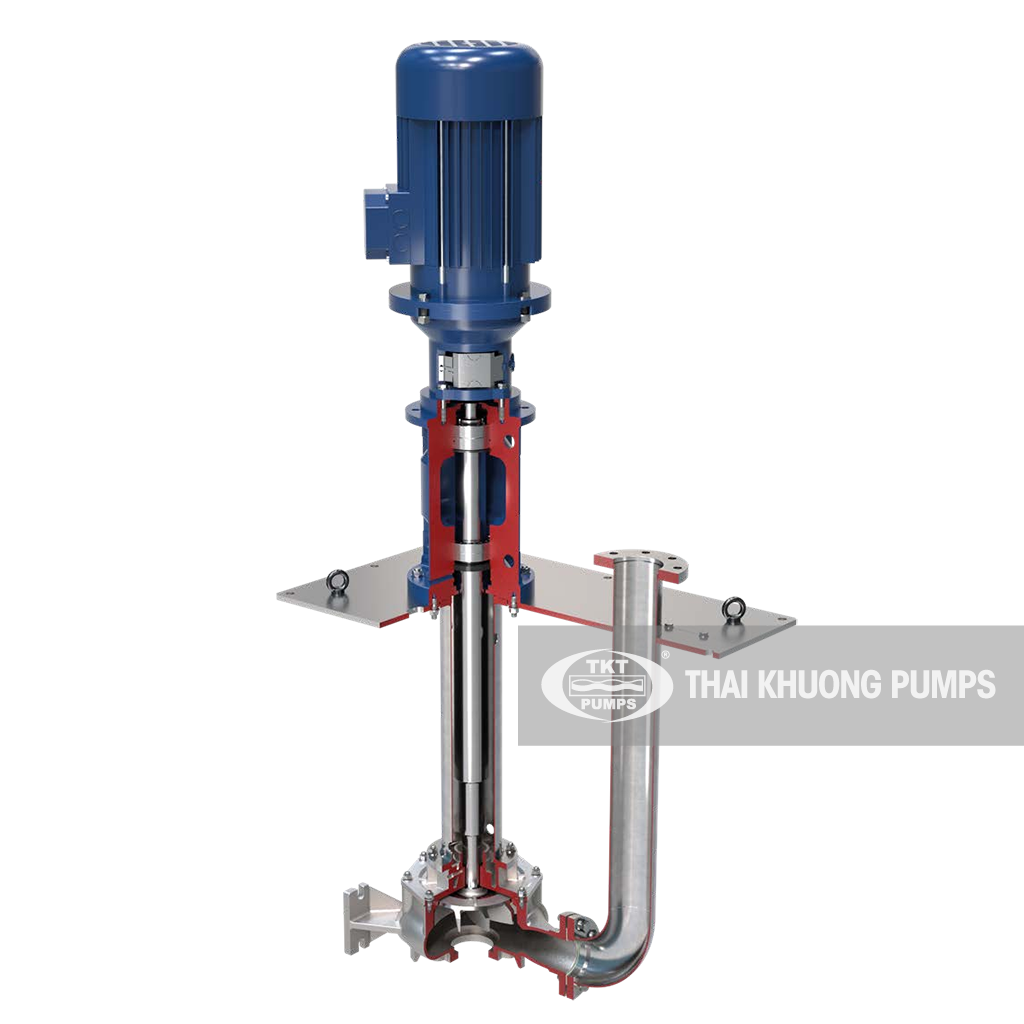

General product information Vertical cantilever centrifugal pumps

The pump body is immersed into the liquid and the motor is mounted above the mounting plate out of the corrosive area. Oversize heavy-duty ball bearings are supplied with grease fittings and located above the mounting plate out of the corrosive area. This means no bearing in the liquid, no seal or bearing bush, and bearing assembly is sealed-off to prevent bearing contamination by liquids or gases-vapors.

This allows the pump to run dry without the risk of damage and so reliable operation and reduced costs.

The possibility to customize mounting plate shape and dimensions, discharge flange position, and column length, allows designers and end-users to match sump or tank plates or flanges.

Vertical cantilever centrifugal pumps structure:

Construction versions of cantilever pump:

Typical installation:

A cantilever pump is installed at the top of the sump/tank and works without level controls. With liquid level above the pump “priming holes,” the pump works properly but as soon as the liquid level is below the suction port, the pump will be unprimed and work dry. The pump will restart to work when the liquid level reaches the pump “priming holes”.

Typical installation with suction extension:

A cantilever pump is installed at the top of the sump/tank and works without level controls. With liquid level above the pump “priming holes,” the pump works properly but as soon as the liquid level is below the end of suction extension or when NPSHa is lower than NPSHr, the pump will be unprimed and work dry. This arrangement allows emptying tanks up to 5 meters below the suction port. The pump will restart to work when the liquid level reaches the pump “priming holes”.

External installation:

A cantilever pump is installed beside of sump/tank and works without level controls. When the liquid level inside the tank is above the pump casing, the pump can operate but as soon as the liquid level is below the suction port, the pump will be unprimed and work dry. The pump will start again to work when the liquid level inside the tank is above the pump casing. The liquid level inside the tank must be lower than the recirculation pipe in order to allow the liquid back into the tank and not damage the motor. This arrangement allows working with very hot fluid (up to 300°C) with suspended solids.

*Technical team/consultant Thai Khuong Pumps is ready to connect to support you with information about industrial pumps as quickly as possible. Contact immediately with Thai Khuong Pumps, so we can support you better.