1000 Series Lubrication Pumps

1000 Series pumps are based on the proven internal gear principal, and have been enhanced in response to demands from our OEM customers for a pump that offers advanced features which make installation easier. These side-ported pumps have the option to bolt SAE/DIN flanges onto them ensuring maximum flexibility on the porting arrangements. Tuthill’s goal was to design a pump that meets your technical requirements and is easily fitted into your system. The 1000 Series pumps are mechanical seal fitted and have a Carbon Bushing Idler as standard. Options are available for lip seals on direct mounted pumps and a choice of ball bearing or carbon bearings in the body.

FEATURES 1000 Series Lubrication Pumps

- Body: EN/GJL/250

- Rotor: Carbon Steel

- Idler Gear: Sintered metal or steel

- Self Priming

- Non-pulsating flow

- Mechanical seal fitted as standard (lipseal option only on direct mounted pumps)

- Choice of ball bearing or carbon bearings in body. Carbon Bushing Idler is standard

- Max speed: 1008-1010 up to 3600 rpm and for 1012-1024 up to 1750 rpm

- Max differential pressure 18 bar (261psi) For higher pressure consult the factory

- Max inlet pressure 45 bar (653psi) Dependent on type of mechanical seal fitted

- Max temperature 200ºC (392ºF)

- Modular design for ports and bushings

- Flange has an o-ring seal

EASE OF MAINTENANCE 1000 Series Lubrication Pumps

No labour to line up motor

Unique seal flush system for prolonged life

Pumps can be removed from the system without having to unthread any pipework, ensuring quick and leak free installation

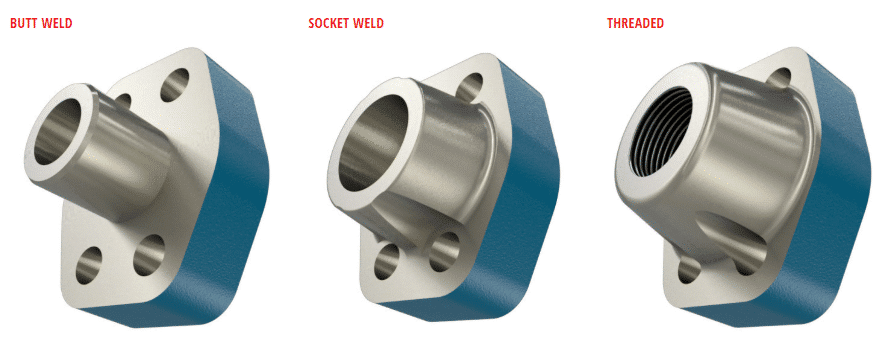

PORTING 1000 Series Lubrication Pumps

The 1000 Series pumps are fitted with SAE/DIN flanged ports, which enable Tuthill to offer various port options. Tuthill has the ability to build your pump with threaded, butt weld, socket weld ports, or a blank flange. The blank flange can be tapped to your specific requirement.

MOUNTING 1000 Series Lubrication Pumps

The 1000 series is designed to be close-coupled directly to IEC or NEMA motors. This compact mounting process enables a smaller footprint, but also automatic shaft alignment when changing pump heads.

Vertical mounting optimizes the fit of the pump into smaller footprints. This is a highly requested configuration whenever floor space is limited. It is recommended that if the pumps are to be mounted in this manner, it is indicated at the inquiry stage of the buying process.

All the adapters can be supplied with a tapped port to facilitate the fitting of a clear bottle. The bottle is used as a sight glass to determine seal status.

The 1000 series symmetrical design provides added flexibility. The pump head can be rotated in 90° increments, creating the ability to change port alignment from horizontal to vertical or reversing suction and discharge ports.

1000 SERIES SPECIFICATION DATA

ASSEMBLY 1012 TO 1017

*Technical team/consultant Thai Khuong Pumps is ready to connect to support you with information about industrial pumps as quickly as possible. Contact immediately with Thai Khuong Pumps, so we can support you better.

Reviews

There are no reviews yet.