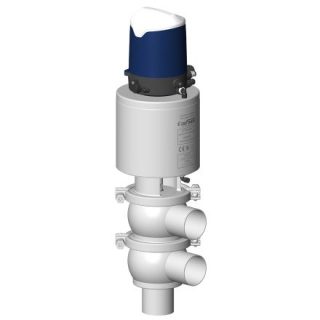

DCX4 diaphragm divert valve are used in a wide variety of process and ancillary fluid applications, designed for efficient cleaning. The aseptic bearing shut-off valve is fitted with a fluid (cleaning/rinsing) or vapor circulation bearing. For aseptic applications, the DCX4 valve can be equipped with a diaphragm PTFE ensuring a physical barrier between the interior of the valve and the external environment.

DCX4 diaphragm divert valve – Definox

Product Description

TOP-FLO® Definox Diaphragm DCX3 – DCX4 Single Sealing Shut Off and Divert Valves

SPECIFICATIONS

Size Range: 1”, 1-1/2”, 2”, 2-1/2”, 3”, 4”, 6”

Materials:

Body/Stem: 316L SS

Operator: 304 SS

Valve seals: PFA floating plug seal, PTFE diaphragm type stem/body seal

Optional seals: EPDM, FKM, or Silicone plug seal

Connections: OD tube butt weld, Sanitary clamp, Others upon request

Options: Dual micro valve alcohol barrier

Signal Equipment: ICS Control top – valve sizes 1” – 3”, ACS Control top – valve sizes 4” – 6”, Network options: point-to-point & AS-i (others upon request)

Surface Finish: Ra Interior = 32Ra, Ra Exterior = 40-50Ra

– From DN 25 to DN 150

- SMS, DIN or US versions.

– Deformable PTFE diaphragm

- Surface area of the diaphragm equivalent to that of the plug, helping to balance the pressure

- Alcohol barrier, optional

– Dismantable actuator

- Easily transformed: Normally Open NO, Normally Closed NC or Double Acting DA.

– Leak indicator

- Providing a visual indication of a leak in case of diaphgram failure.

– Mass-machined spherical body

- Body configurations available: L/L, T/L, L/T, T/T, L/X.

– One-piece plug with PFA floating seal

- Sturdy design avoiding any risk of breakage or unscrewing.

Technical Advantages DCX4 diaphragm divert valve

– Patented PFA floating plug seal that is easily cleaned during CIP and offers outstanding sealing at high temperatures and excellent chemical resistance.

– PTFE diaphragm type stem/body creates a barrier between the interior of the valve and the outside environment.

– Integral micro valve to indicate PTFE diaphragm failure.

– Heavy duty stainless steel pneumatic actuator that is capable of function changes: NO (Normally Open) – NC (Normally Closed) – DA (Double Acting).

– Clamp style operator connection (manual and automated) for easy inspection and maintenance.

– Heavy wall machined spherical bodies guarantee excellent resistance to thermal expansion and contraction.

– Wide variety of body configurations: DCX3 (L) – (T) – (X) / DCX4 (L/L) – (L/T) – (T/L).

Replacing pfa seals DCX4 diaphragm divert valve

Service Conditions

Max. temperature: 284°F (depending on seal type)

Min. temperature: 34°F

Max. working pressure: 116 psi

Actuator air supply: 80 psi Minimum / 116 psi Maximum

Vacuum resistance: 0.4 cm3/s

Application of DCX4 diaphragm divert valve

With the above outstanding advantages, defines valves are very popular with investors in many fields such as:

– Food, pharmaceutical, chemical, and cosmetic industries

– Animal feed processing industry,…

Get the detailed specification file of the DCX4 diaphragm divert valve here:

*Technical team/consultant Thai Khuong Pumps is ready to connect to support you with information about industrial pumps in the fastest way. Contact Thai Khuong Pumps immediately, so we can better assist you.