DH-JH progressing cavity pumps series

-

- Name: DH-JH (With Hopper) PUMP

- Class: DH-JH DIAMOND SERIES

- Type: PROGRESSIVE CAVITY PUMP

- Application: Wastewater treatment, chemical, petrochemical, paper industry, mining, construction, ceramic, food,…

- Origin: Italia

- Brand: NOVA ROTORS

- The product is officially distributed in Vietnam by Thái Khương Pumps

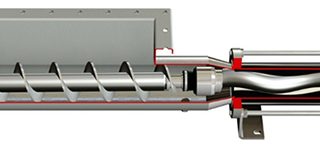

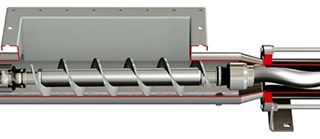

The Diamond Series with hopper and auger feed progressing cavity to convey directly the product to the hydraulic part.

Ideal machines for pumping viscous and non-flowing, with a very high solids content.

DH and JH Series is the basic version with rectangular hopper and auger feed the hydraulics. The length is customizable depending on the application. Suitable for pumping substances poorly flowing up to 18% of dry substance which does not tend to form a bridge.

Specifications of DH-JH progressing cavity pumps series

The important parameters of Nova Rotors’ DH-JH progressing cavity pumps line are announced by the company as follows:

-

- Maximum pump capacity: 400 m³/h

- Maximum working pressure up to: 48 bar

- Maximum working temperature up to: 180°C

- NPSHr: 3 m

- Available sizes: from size 025 to size 300

Classification of DH-JH progressing cavity pumps series

The DH and JN series are distinguished for the type of fitting of the progressing cavity pumps to the drive.

DH Series

DH Series: the drive is coupled directly to the pump via a flange. This solution is extremely cheap and compact, considerably reducing installation costs and simplifying maintenance. The stress generated by the hydraulic part is supported by the drive itself. Each drive used is adequately selected based on their specific technical parameters and are subject to numerous duration tests with heavy loads.

JH Series

JH Series: the drive is connected to the shaft inlet via a coupling joint. This configuration is the best solution in terms of performance and durability. All the stress generated by the pump is absorbed by the bearings in the housing. These bearings have very high resistance against loads. They are assembled with extreme precision on the highest quality manufactured parts. It is the best solution when you want to guarantee duration and reliability, yet with greater installation space requirements. The bearing housing designed by us is modular and can be installed after a pump with the JX series block housing. It is state of the art for this type of installation.

Application of DH-JH progressing cavity pumps series

The pump with hopper with feed conveyor is suitable for transferring products with high viscosity and high solids ratio up to about 17%.

Hoppers are required on these products:

-

- Dehydrated sludge contains up to 17% dry solids

- Lake Trat

- Cellulose paste

- Fish carcass

- Soft rock

- And many others

*Technical team/consultant Thai Khuong Pumps is ready to connect to support you with information about industrial pumps in the fastest way. Contact Thai Khuong Pumps immediately, so we can better assist you.