Nova Rotors DM progressing cavity dosing pump new series, with flow rates from 1 l/h to 1 m³/h, pressures from 0-24 bar, is the industry’s best solution for dosing a wide range of liquids. The 3 phrases to describe this dosing pump are stability, reliability, performance and application flexibility.

DM progressing cavity dosing pump – Nova Rotors

Designed for the most demanding requirements, the meter is suitable for dosing viscous or non-viscous fluids, with or without solids of any nature. The DM progressing cavity dosing pump is the ideal solution for those looking for a standard high-tech product at an affordable cost.

Compared to the old MN series pumps, the DM/JM/FM series dosing pumps have a modular design, available in AISI316 or polypropylene. With shaft also constructed of AISI316, Hastelloy C or titanium for corrosive/aggressive chemical applications.

DM progressing cavity dosing pumps are available with a single-phase motor inverter with onboard commands or a compact three-phase gear motor controlled by an external VFD or with an F-flange adapter allowing you to easily mount your favorite gear.

For non-abrasive fluid applications, a polypropylene body configuration is recommended.

Features of the progressing cavity dosing pump DM

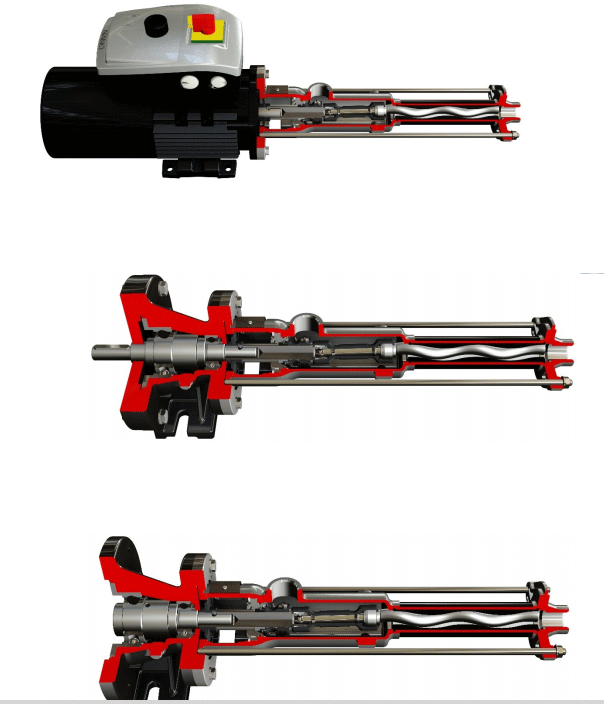

DM dosing pumps are available in 3 mounting types and are distinguished by the type of coupling of the pump chamber to the motor.

DM Series

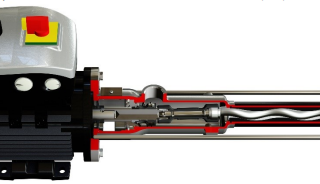

The actuator is coupled directly to the pump via a flange. This solution is highly economical, compact and significantly reduces installation costs, and simplifies maintenance. The stresses generated by the hydraulic part are taken up by the motor itself. Each motor used has been selected to strict specifications and subjected to numerous endurance tests under heavy loads. The DM series is the standard for most pumps installed in the industry.

JM series

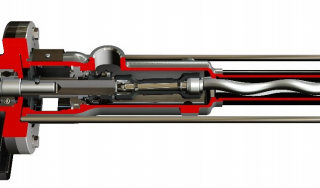

The actuator is connected to the pump inlet shaft through a coupling. This is the best solution in terms of performance and durability. All forces generated by the pump are absorbed by the bearings in the rack.

These bearings have very high load capacity, they are mounted with extreme precision. It is the best solution when optimum levels of durability and reliability are required while increasing installation space. The bearing housing is modular and can be flexibly installed in the DM series dosing pumps

FM Series

The actuator is connected directly to the pump through the flange of the bearing housing module. This is the most flexible mounting type as it allows the use of reducers with standard flanges and output shafts, couplings with hydraulic or pneumatic motors, maintaining the simplicity and compactness of the combined solution traditional tight and at the same time guarantee the total reversibility and outstanding performance of the bearing housing.

This load-bearing module can be applied to the entire DM, JM, FM series dosing pumps and allows for quick maintenance of the drive unit. The FM is therefore a modular and reliable dosing pump with all types of motors.

Outstanding advantages of the progressing cavity dosing pump DM

The DM series progressing cavity dosing pump has outstanding advantages that can be mentioned as:

-

- Various sealing systems are available including a single mechanical seal with or without quenching, dual opposing and parallel seals. Quench and double seals must be flushed according to the API appropriate to the process. A wide range of seals conforming to ISO\EN 12756 can also be installed to meet all application requirements.

- The pump housing is extremely sturdy, suitable for load-bearing.

- The large suction unit allows for excellent priming, and efficient volume and dosing of the viscous fluid. Pump housings can be made of different metals according to UNI EN / GAS requirements

- Stainless steel rotating parts as standard. Several different metals are available. Various driveshaft options on request

- Connected to the motor via the bearing. This is the simplest solution in regards to maintenance and allows the pump to rotate in reverse. Bearings protect drive shafts from corrosion.

- The wear-resistant rotor and stator enable the pumping of highly viscous liquids with solids. The rotor is available in different base materials and is heat-treated or coated for added durability. The stator is also available in a variety of configurations.

- Motoinverter: Save energy by adjusting the speed. Can be programmed and controlled by PC via USB or wirelessly by smartphone or tablet via Bluetooth

Application of the progressing cavity dosing pump DM

With the above outstanding advantages, DM Nova Rotors dosing pump is very popular with investors in many fields such as:

-

- Food, pharmaceutical, and cosmetic industries

- Animal feed processing industry…

- Paper production

- Industrial and marine, including; oil transfer, sewage transfer

*Technical team/consultant Thai Khuong Pumps is ready to connect to support you with information about industrial pumps in the fastest way. Contact Thai Khuong Pumps immediately, so we can better assist you.