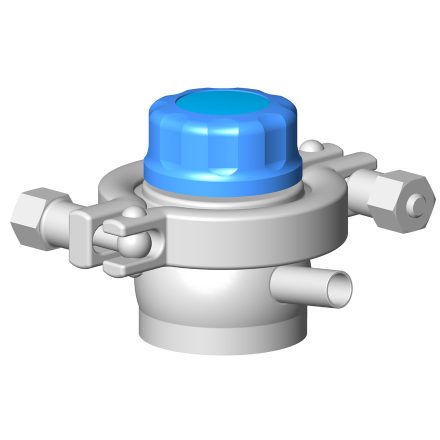

VDMX DMAX diaphragm valve are used in a wide variety of process and ancillary fluid applications, designed for efficient cleaning. The aseptic bearing shut-off valve is fitted with a fluid (cleaning/rinsing) or vapor circulation bearing.

The DMX DMAX diaphragm valve allows for retention free flow and a constant flow diameter. Its design, integrating a physical barrier between the interior of the valve and the external environment, makes for a valve particularly adapted to the pharmaceutical industry.

VDMX DMAX diaphragm valve – Definox

Features

- No product entrapment areas that prevents the development of bacteria

- Retained passage diameter

- Low loss of pressure

- Quick assembly and disassembly; easy maintenance

- Easy to adjust operating devices

- Machined solid body to guarantee good material uniformity

- Valve can be washed and sterilised

- Leak detection in case of deterioration of the diaphragm

– From DN 8 to DN 51

- SMS, DIN or US version.

– FDA 3A certified diaphragm

- PTFE composite diaphragm

- Inert to cleaning solutions (CIP), solvents, essential oils.

– Ergonomic handle

- Plastic material PBT, offering high resistance against chemical agents up to 130°C

- Stainless steel version, optional.

– 4 levels of internal finishes

- Standard

- Internal polish

- Internal and external finishes

- Electropolish.

– Mass-machined body

- Possible sterilization up to 140°C

- Body profile without retention zone.

– Clamp assembly

- Fast disassembly and modification of the operating devices

- Centering and homogeneous tightening of the diaphragm.

Technical Advantages VDMX DMAX diaphragm valve

- Body: stainless steel 1.4404/ 316L

- Handle: plastic material PBT (thermoplastic polymer polyester), stainless steel 1.4301 / 304 on request

- Actuator: stainless steel 1.4301 / 304

- Diaphragm: uniform composite diaphragm (PTFE and elastomer) FDA/3A certified, EPDM or silicon diaphragm

Replacing pfa seals VDMX DMAX diaphragm valve

– Max. temperature: +140oC/+284oF

– Min. temperature: 0oC/+32oF

– Max. working pressure:

-

- 10 bar (1000kPa) / 145 psi elastomer diaphragm from DN10 to DN25

- 6 bar (600 kPa)/ 87 psi elastomer diaphragm from DN32 to DN51

- 8 bar (800 kPa)/ 116 psi PTFE diaphragmVacuum resistance elastomer diaphragm: 10-6 mbar, helium tightness (leakage rate): 10-6 atm.cm3/s

- Vacuum resistance PTFE diaphragm: 10-3 mbar, helium tightness (leakage rate): 10-3 atm.cm3/s

- Actuator air supply pressure:

- min. 5.5 bar (550 kPa)/80 psi

- max. 8 bar (800kPa)/116 psi

- Fatigue resistance:

- 100 000 cycles elastomer diaphragm

- 40 000 cycles PTFE diaphragm

Application of VDMX DMAX diaphragm valve

With the above outstanding advantages, defines valves are very popular with investors in many fields such as:

– Food, pharmaceutical, chemical, and cosmetic industries

– Animal feed processing industry,…

Get the detailed specification file of the VDMX DMAX diaphragm valve here:

*Technical team/consultant Thai Khuong Pumps is ready to connect to support you with information about industrial pumps in the fastest way. Contact Thai Khuong Pumps immediately, so we can better assist you.