Nova Rotors’ Diamond series DV progressing cavity pumps has an adjustable length. This is one of the highlights of this pump line. Let’s see more about DV progressing cavity pump through the content below!

The progressing cavity pumps DV series

General information of DV Diamond Series industrial progressing cavity pumps – Nova Rotors:

-

- Name: DV PUMP

- Class: DV DIAMOND SERIES

- Type: PROGRESSIVE CAVITY PUMP (SCREW PUMP)

- Application: Wastewater treatment, chemical, petrochemical, paper industry, mining, construction, ceramic, food,…

- Origin: Italia

- Brand: NOVA ROTORS

- The product is officially distributed in Vietnam by Thái Khương Pumps

DV progressing cavity pumps – the vertical series is the ideal solution for pumping from wells or tanks. It is suitable for pumping viscous and non-viscous products as well as abrasive or aggressive ones.

Available with outlet flange connections UNI, DIN, ANSI and GAS BSP.

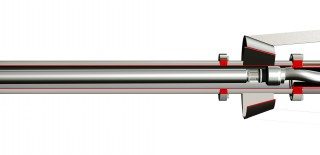

The length is totally customizable according to the setup requirements. The stainless steel version (AISI 304 or AISI 316) has a protective jacket that covers the stator as standard to prevent it from corrosion.

Classification of progressing cavity pumps DV series

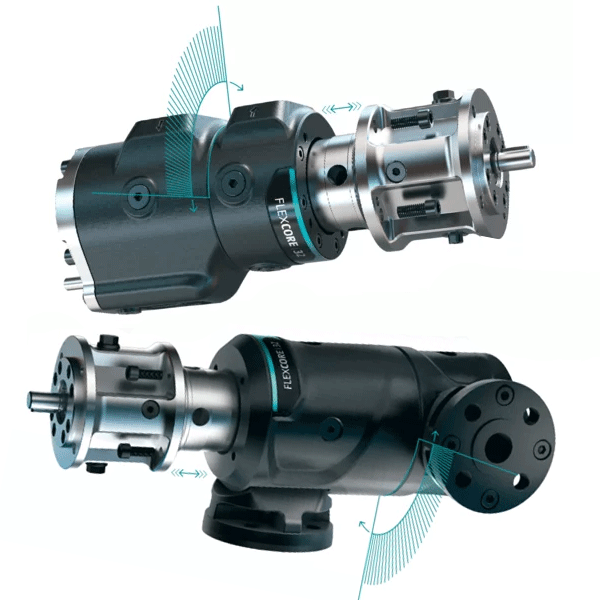

There are two standard configurations availables: the short version and the long version.

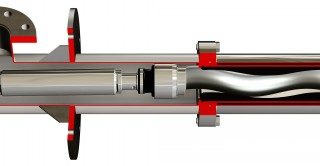

The difference is in the length of the installation with which they are required for. The short version is compact, robust, easy to install.The long version instead allows installation in deep wells or tanks, and presents a complete series of dedicated optimizations such as the removable inlet for easy maintenance of the rotor, stator and coupling.

A fundamental characteristic is the support of the downhole baseplate, with a clamping cone which makes the pump very stable and vibration free even in extreme conditions of use.

Both series are always configured in a monobloc arrangement.

DV progressing cavity pump short version

Designed in a minimalist, compact and solid architectural style. The pump can be installed with an anchor plate for a secure position in industrial fluid pumping operations.

DV progressing cavity pump long version

This pump plate requires mounting on a base to minimize vibrations and oscillations caused by the length of the pump body. With the size and structure partially immersed in the liquid, this design reduces the negative suction head, making it easier for the pump to suck up the fluid. Another special feature is that we can replace the cone plates when needing to repair and maintain the pump.

Application of DV progressing cavity pump

Vertical DV progressing cavity pumps are designed to draw liquids easily from tanks, kegs, tanks or wells. Vertical pumps can move:

-

- Sludge in the processes of wastewater treatment, mining, oil extraction

- Very viscous liquids in the production of paper, cosmetics, plastics, paints

- Corrosive products in the process of chemical, petrochemical, medical pharmaceutical production systems…

*Technical team/consultant Thai Khuong Pumps is ready to connect to support you with information about industrial pumps in the fastest way. Contact Thai Khuong Pumps immediately, so we can better assist you.