L Series Lined Slurry Pumps similar in design to the Schurco® S Series (Warman® AH®), the L Series has the same rugged design features with higher efficiencies. It is offered fully lined with split outer casings.

Schurco Slurry® L Series pumps maintain the ruggedness and slurry handling capacity of the S Series, but with a wider range of flow rates and lower life-cycle costs. Higher efficiency impellers make the L Series a valuable feature in any plant.

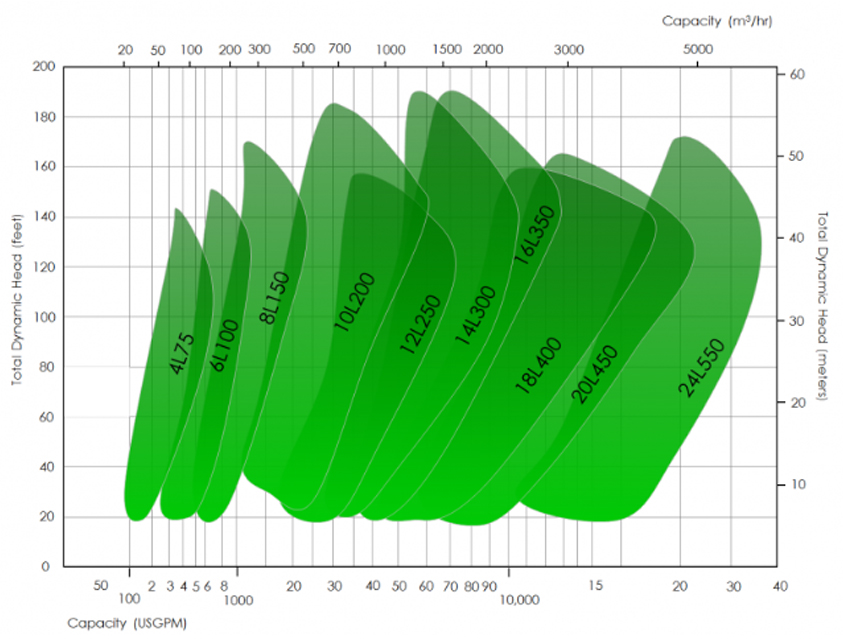

L Series Lined Slurry Pumps Profile

- Discharge Diameters 3” to 22” (75mm to 550mm)

- Heads through 180ft (55m)

- Flow-rates through 30,000gpm (6,8 00m3/h)

- Casing pressure tolerance to 250psig (1,725kPa)

L Series Lined Slurry Pumps Features

Value

- Flow-rate and head delivered at reduced initial and life-cycle costs with greater efficiency over the S series

- Designed for Class III and below slurries, retaining the ruggedness of a heavy-duty slurry pump

Wetted Parts

- Impellers – higher efficiency rates (up to 90+ %) – pump out vanes to reduce recirculation within pump, and aid in preventing seal contamination; Impeller clearance is adjustable to maintain efficiency over the life of the part.

- Liners – Alloy or thick elastomer liners provide superior erosion and corrosion resistance

Seals

- Expeller (Centrifugal Seal) – no external sealing water required where applicable

- Stuffing Box – flushed gland sealing with braided packing and a lantern ring

- Mechanical Seals

Bearing Assembly

- Cartridge-style bearing housing allows for removal from pump and assembly in controlled environment

- Oversized shaft diameters and reduced overhang in the wet-end contribute to long life and reliability in the field

Interchangeable with Warman® L Series pumps.

Selected Applications L Series Lined Slurry Pumps

- ball mill discharge

- rod mill discharge

- Ni acid slurry

- coarse sand

- coarse tailings

- phosphate matrix

- minerals concentrate

- bottom/fly ash

- lime grinding

- oil sands

- mineral sands

- fine tailings

- phosphoric acid

- coal

- flotation

- process chemical

- pulp and paper

- FGD

- wastewater

*Technical team/consultant Thai Khuong Pumps is ready to connect to support you with information about industrial pumps as quickly as possible. Contact immediately with Thai Khuong Pumps, so we can support you better.