NOVA ROTORS

Nova Rotors are Progressing Cavity Pump Specialists offering a complete range of reliable, efficient, and cost-effective pumps for all industries.

Nova rotors were founded in 1990, applied in different sectors, from wastewater treatment plants both civil and industrial, to oenological and the food sector. Nova Rotors, certified ISO 9001:2008 and e OHSAS 18001:2007, guarantees an efficient way of working which is evident in the product and in the quality of service in terms of lower costs, punctual delivery, and best performances.

Moreover, Nova rotors pump with ATEX proof which is required for applications in explosion areas. The range is characterized by a big choice of models covering a field of capacity up to 420 m3/h and pressures up to 48 bar in order to satisfy different market needs.

Nova Rotors Range

Progressing Cavity Pump Specialists

A complete range of reliable, efficient and cost-effective pumps for all industries including:-

Oil & Gas (API 676) – Biogas – Waste & Sludge – Paper Making – Food & Drink

- Flows up to 400m3/hr

- Pressures up to 48 barg

- Temperatures from -40 to 150 deg. C

Diamond Series Pumps

“Diamond” series modular designs to suit your application

Nova Rotors presents its new range of progressing cavity pumps called the Diamond Series.

Completely renewed mechanics to increase the performance with a new aggressive design. These pumps are completely reversible.

The Diamond series is based on the concept of modularity in every characteristic: hydraulic parts, casing, seals, base plates, housing, drive shafts. Each part can be manufactured in a series of variants without changing the structure of the machine while keeping the main spare parts standard. Maximum flexibility for an upgrade, retro-fit, or duty change. The “Diamond” pump range is available in two basic configurations:-

DN Series: the drive is coupled directly to the pump via a flange for a cost-effective and compact design.

JN Series: the drive is connected to the free bare shaft inlet via a flexible joint coupling. This configuration is the best solution in terms of performance and durability as all the forces generated by the pump are absorbed by the specifically designed heavy-duty bearings in the housing.

Available in a wide pumps range.

1)DHE diamond series

2)DHS-T-JHS-T diamond series

3)DV diamond series

4)DX-JX diamond series

5)DHB-JHB diamond series

6)DHP-JHP diamond series

7)DHSB-JHSB diamond series

8)DHS-JHS diamond series

9)DH-JH diamond series

10)DN-JH diamond series

Engineered Design for Lowest Life Cycle Cost

DN/JN Flanged Industrial Series

Including API 676 and Hygienic designs

- Flows up to 110 m3/hr

- Pressures up to 48 barg

- Temperatures from -40 to 150 deg.C

- Self-priming up to 7 metres

The Nova Rotors Diamond series has been designed for strength, reliability, performance and application flexibility. By focusing on quality engineering and ease of maintenance, the Nova Rotors Diamond series has extremely low, industry beating life cycle costs

The standard flanged inlet and outlet design, available in a wide range of materials to suit most liquid applications. Available either direct coupled as “DN” type or with coupling and bearing housing as “JN” type

DH/JH Hopper Series

With hopper and auger feed screw to convey the product to hydraulic pump end, these machines are ideally suited to viscous and non-flowing liquids with a very high solids content.

With all the advantages of the modular and low life cycle costs of the Diamond series design, the hopper range includes multiple variations to suit all applications.

All units available as either direct drive (DH) or with coupling joint and bearing housing (JH).

A wide range of hooper design pumps with hydraulic auger feed screw for handling high consistency materials with low flowability and high solids content. As above, available as DN and JN types

DV Vertical Series

The Vertical series is designed for pumping from wells or tank and offers the same design and operational advantages of the other Diamond series pumps.

There are two standard configurations availables: the short version and the long version, both of which can be customised to suit the application

Flow up to110m³/h

Pressure up to 12 bar for the standard series

Temperature from -40°C until to 150°C

API 676 compliant

All the advantages of the modular and low life cycle costs of the Diamond series design, in vertical configuration for demanding tank and well emptying applications

Available with a wide range of discharge flanges and suction inlet to suit the process fluid, these units are designed to pump all manner of materials, including viscous, abrasive and aggressive liquids from tanks or wells.

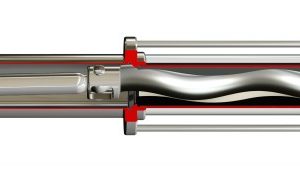

Wobble Series Pump

An extremely compact and versatile design with minimal parts which provides simple and very cost-efficient pumping of a wide range of liquids including those with viscous, solids, or mildly abrasive content. The ideal solution for those seeking a highly compact and versatile product. They are particularly easy and economical to maintain, due to the very small number of component parts.

- Flow rate up to 14,4m³/h

- Pressure up to 4 bar

- Temperature from -40°C up to 80°C

Our range of wobble pumps is the ideal solution for those seeking a highly compact and versatile product. They are particularly easy and economical to maintain, due to the very small number of component parts. They can be used in a variety of industrial applications due to their ability to pump products that are viscous, which have solids in the fluid, or which are mildly abrasive.

Perfect for those seeking a highly efficient, economical product, these offer an unparalleled cost/benefit advantage. Even at high rpm, there is no pulsating and virtually no centrifugal effect. They are also suitable for use within the food industry, as there are no dead zones within the pump.

The RL series range of pumps all have solidly constructed housings in cast iron and stainless steel (AISI Type 304 and AISI Type 316), manufactured using lost wax casting technology. The models are as below:

1)RL wobble series

2)R wobble series

Thai Khuong Pumps as the sole agency of Novarotors can provide client demand in VietNam

Nova Rotor Certificate

Nova Rotor Product

Progressing Cavity Pumps

Progressing Cavity Pumps

Progressing Cavity Pumps

Progressing Cavity Pumps

Progressing Cavity Pumps

Progressing Cavity Pumps

Progressing Cavity Pumps